Pickling line for tube and rod profile

With the innovative HyperCrane™as the technology platform, we have innovated and optimized the tunnel automatic tube bar profile pickling line from various aspects such as process, fluid, energy saving and environmental protection, machinery, control and software, especially the application of machine vision technology, presenting a 21st century tube and bar profile pickling technology to the industry, which fully meets the requirements of Industry 4.0 for advanced manufacturing.

A number of patents have been filed around this technological innovation and provide a strong legal guarantee for our sustainable development.

Innovation remakes pickling technology!

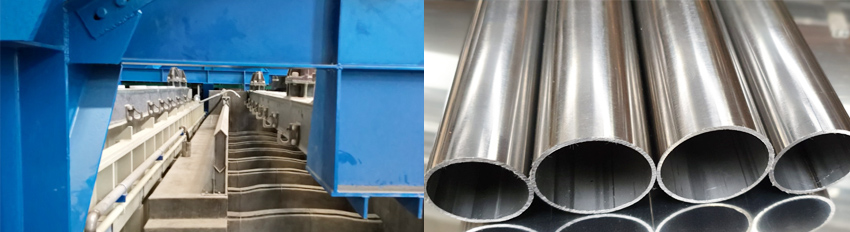

i. Tube pickling line

High-quality steel tubes have strict requirements for surface quality, and the surface quality of the inner surface is the most critical, and also bring the most headache to tube manufacturers. Based on advanced machine vision technology, we have developed the world's first full-automatic spray technology for inner surface, so that production workers can completely get rid of the impact of harsh working environment on human health.

Whether it is carbon steel or stainless steel, pipe diameter 20 up to 800, we have the most suitable solution for you!

On creating a green working environment, we are serious!

i.Pickling line for pipe fittings

Due to various shapes and complex internal structures, the surface quality of pipe fittings has always been difficult to grasp in the industry, which has also led to the failure of automation efforts of such production lines. As the results traditional pickling lines with open tanks causing serious damage to personnel and the environment are still used. Our latest research and development of the world's first automatic pickling line for stainless steel pipe fitting have completely relieved the customer's worries, and won recognition of the world's top stainless steel pipe fittings manufacturing enterprise - Zhejiang Jiuli!

To protect the environment we live in, every step of improvement is worth it!

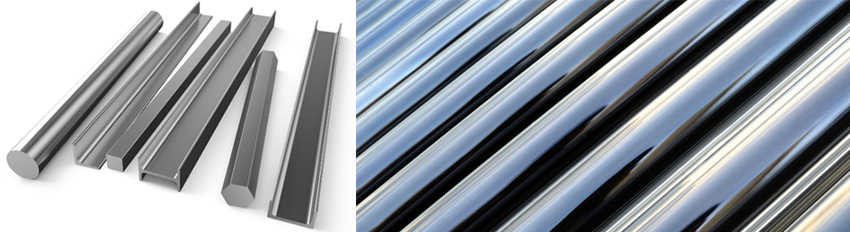

i. Pickling line for rod profiles

The cross-sectional shapes of the rod profiles are different, the length may be tens of meters, and some shapes will be tightly stacked, which brings great difficulties to the pickling process. If the surface rinsing is not considered carefully, the phenomenon of unclean rinsing or surface scratches will occur, reducing the quality level of the product.

Whether it is stainless steel or non-ferrous alloy, round bar, square bar, hexagonal bar, H-beam, flat bar, we can handle it freely!

Create value for customers through quality!